Challenges

Mining companies face numerous challenges when recovering minerals from brines. Processing can be complex and requires high energy and water requirements, making it capital-intensive. With the threat of water scarcity and heightened energy demands globally, organizations are faced with more stringent environmental requirements and increased pressure to operate more sustainably.

Historically, vendors have provided off-the-shelf designs based on their previous experience in adjacent commodities. Thus, companies would get already-commoditized designs instead of custom-engineered solutions. Through advances in modeling technology and improved process understanding, designs can now be customized to the user and the application.

Today, we are encountering challenging process brines more frequently. These require specialized engineering and customization of the crystallization systems. Furthermore, companies are looking for leaner, more efficient, and cost-effective mineral recovery.

We can help.

With our custom crystallization technology, we can offer our clients improved performance, operability, and maintenance over traditional systems. We understand processes outside the crystallization unit scope boundary, and can thus optimize the equipment design to suit the overall process. Our fundamental understanding of key technical areas associated with design, testwork, implementation, commissioning, and operations of crystallization equipment means that we can provide real benefits through customized solutions.

All aspects of the design and selection of appropriate equipment for crystallization systems are guided by our core emphasis on safety, operability, and the selection of suitable materials of construction.

Solutions

As the world seeks to mitigate the impacts of climate change and ensure long-term food supply, there is an increased demand for lithium and other battery metals, and potash. We are well-positioned to differentiate ourselves in these pivoting and emerging markets by:

- taking a more holistic view of the heat and mass balance, integrating the crystallizer with the balance of plant for improved CAPEX and OPEX results

- utilizing advanced analytical tools, such as Computational Fluid Dynamics (CFD), to optimize the vessel design

- providing consistent engineering deliverables and equipment through the plant

- including world-class crystallization subject matter experts in the technology team

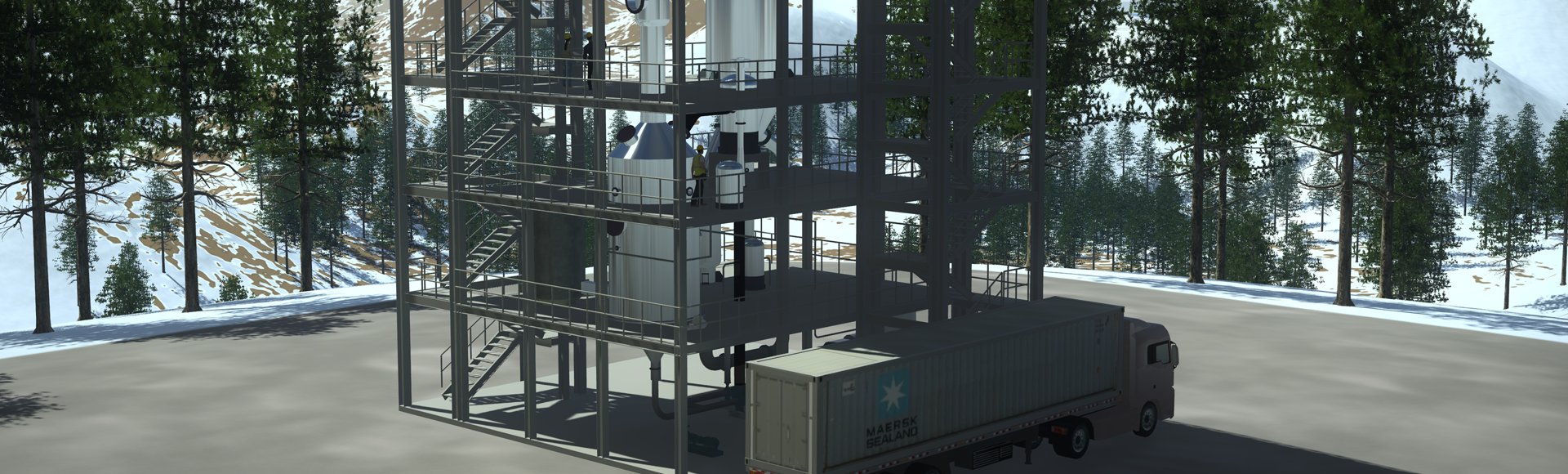

- leveraging our project delivery experience and tools, including modularization and the Building Information Modelling (BIM) tool

- offering related services, such as digital solutions for process monitoring and advisory and predictive maintenance

Our team also provides a full range of engineering services for the refurbishment of existing units to improve performance or modify end-use. We have the capability to offer crystallizer packages with a variety of commercial models such as EPCM, design/supply, or turn-key.

We are committed to our clients’ success. Our engagement extends far beyond the construction period and the start-up of a new technology. It is our priority to ensure that the technology equipment meets the operational and production expectations. We will provide on-site operational expertise until these expectations and the performance guarantees are met.

Benefits

- With our custom crystallization technology, we can offer our clients improved performance, operability, and maintenance over traditional systems.

- We understand processes outside the crystallization unit scope boundary, and can thus optimize the equipment design to suit the overall process.

- Real benefits are rooted in our fundamental understanding of key technical areas associated with design, testwork, implementation, and operations of crystallization equipment.

- The design and selection of appropriate crystallization equipment is guided by our core emphasis on safety, operability, and the selection of suitable materials of construction.