Determining the optimal material handling system and design can be a challenge

The global bulk material handling (BMH) market is currently poised for incredibly strong growth. This is a direct result of a growing demand in construction and mining activities for bulk material handling products and technologies, as well as a rise in the automation in mining and mineral processing industry.

You need robust operational solutions that are unique to each resource challenge.

Solutions to maximize throughput, prevent build-up and associated blockages, and minimize impact and wear on interfaces

Whether a new plant, mine or terminal, resource replacement, or existing facilities overhaul, DEM effectively drives capital efficiency by analyzing the flow of material and identifying potential issues and design solutions.

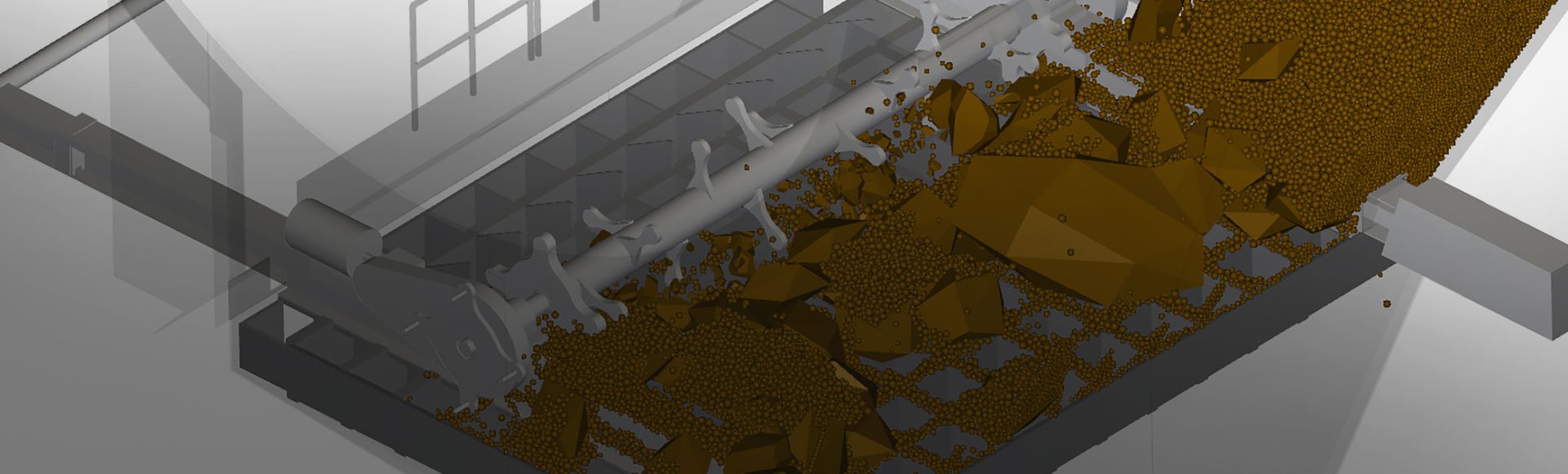

DEM is used for a range of products from free-flowing materials to cohesive concentrates and ores.

It provides techniques and opportunities to optimize the function and performance of transfer chutes, demonstrating how to maximize throughput, prevent build-up and associated blockages, and minimize impact and wear on interfaces.

Both simple and complex particle shapes are possible, facilitating the analysis of porosity and segregation characteristics when analyzing screening, crushing, and storage processes.

Coupled simulations

DEM can be coupled with computational fluid dynamics (CFD), multi body dynamics (MBD), and finite element analysis (FEA), which allows a range of bulk materials handling equipment to be analyzed.

CFD allows air flow to be visualized for use in dust generation modeling and provides a method for verification of passive and active dust control measures.

MBD and FEA can be incorporated into DEM simulations to analyze the dynamic behavior of equipment, including tipplers and storage bins.

Wear and breakage

DEM modeling is used to investigate wear performance of equipment on a relative basis, demonstrating improvements of design changes over the existing system.

Particle breakage modeling is also possible in DEM with a range of particle types able to be simulated and analyzed.

These two areas of analysis are key in ensuring bulk materials handling equipment and systems are effective for the type of material being handled, as well as ensuring longevity of components.

DEM is for a range of bulk materials handling areas including:

- Particle segregation and mixing

- Silo quaking

- Particle breakage and degradation

- Cohesive materials (blockages and build-up)

- Dust control

- Wear analysis (impact and abrasion)

- Flow control and debottlenecking

- Comminution and crushing analysis